Context

Aubert & Duval, a specialist in high-end metallurgy, is a world leader in the design, development and manufacture of forged and closed-die forgings, bars and powders in high-performance steels, superalloys, aluminium and titanium.

In order to control and optimise product microstructures, Aubert et Duval carries out laboratory tests on specimens and develops models to predict microstructural changes (recrystallised fraction and size of recrystallised grains) under the effects of temperature and deformation.

These phenomenological models use as inputs information on the initial structure, thermomechanical data and constants identified by an inverse method using a solver.

Aubert & Duval observed a certain amount of dispersion between the outputs of their recrystallisation models and their measurements from torsion and compression tests. Aubert & Duval therefore called on Phimeca’s skills to help them enrich/improve their recrystallisation models.

Objectives

- Provide Aubert & Duval with tools to better visualise the behaviour of the data at their disposal;

- Improve their recrystallisation model by testing other methods to optimise the constants of the phenomenological models;

- Build a Machine Learning model to predict the recrystallised fraction and the size of recrystallised grains, in order to see what contribution a purely data-based approach can make.

Results

- Descriptive analysis of available data using Python notebooks and the Persalys tool:

- Histograms;

- Boxplots;

- Correlation matrix;

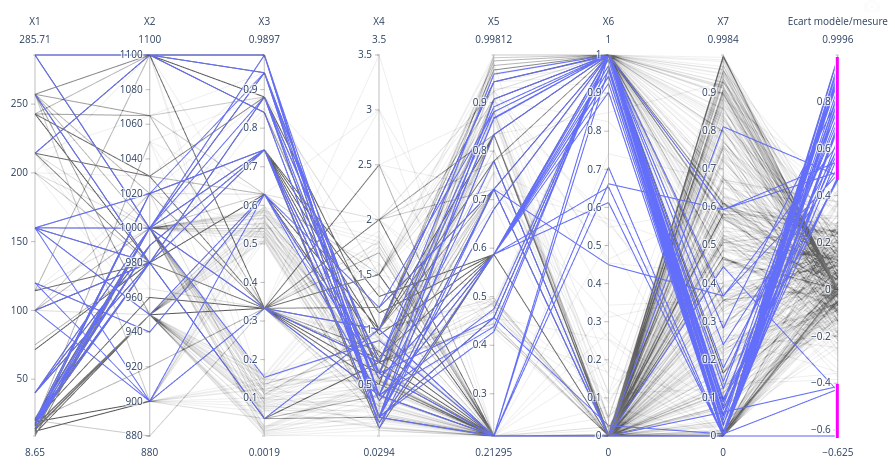

- Parallel coordinate diagram to establish links between the values taken by different variables;

- …

- Python implementation of the phenomenological models supplied by Aubert & Duval.

- Use of different approaches to optimise the constants of the phenomenological model of the recrystallised fraction:

- Gradient descent optimisation methods, with and without constraints;

- Differential evolution algorithms (inspired by genetic algorithms and evolutionary strategies).

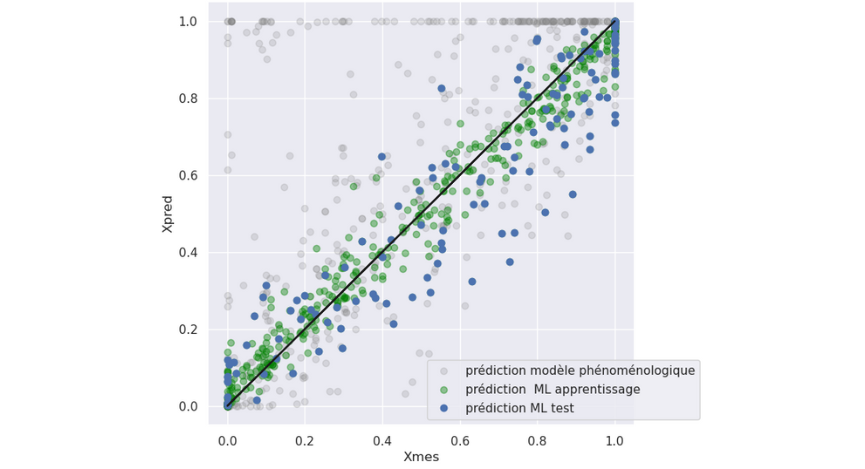

- Construction of Machine Learning models to predict the recrystallised fraction and the recrystallised grain size. Extraction of the importance of the variables in predicting the model.

- Provision of the Persalys tool and interactive notebooks summarising the results of the study and enabling customers to explore their data themselves.

Figure 1 : Parallel coordinate graph to identify links between input variables and deviations between model and measurements

Figure 2 : Graph showing the match between the measurements and the predictions of the phenomenological and Machine