Context

Safran Additive Manufacturing Campus wants to set up an uncertainty propagation chain on a hybrid digital simulation model of the additive manufacturing process, with the aim of identifying the influential parameters and thus controlling the process. The hybrid model comprises two simulation phases with different types of input: scalar and field. The outputs of the first phase of the model are correlated 3D fields, which are also the inputs for the second phase of the model.

Results

- Development of Python scripts to infer the data available for certain input variables and thus build the probabilistic model.

- Generation of designs of experiments representative of the variability range of the model inputs.

- Implementation of a procedure to automate the construction of files to launch the calculation of each of the points in the design of experiments.

- Construction of Kriging-type metamodels replacing the first phase of the hybrid model on the basis of the evaluated experimental design.

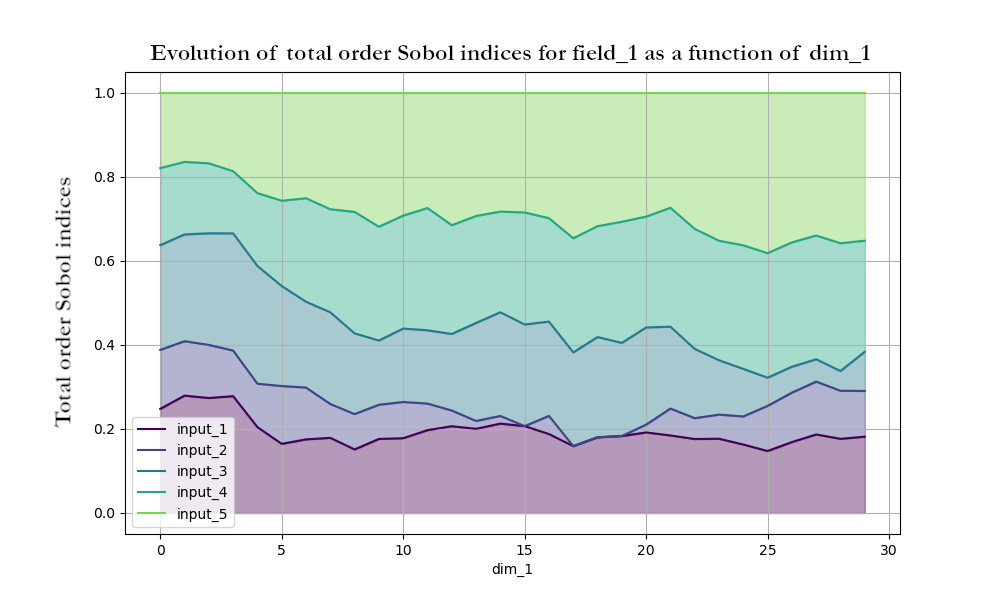

- Identification of the parameters influencing the output fields of the first phase, after calculation of the corresponding Sobol indices.

- Construction of a second metamodel coupling a Principal component analysis (PCA) and chaos polynomials to replace the second phase of the model.

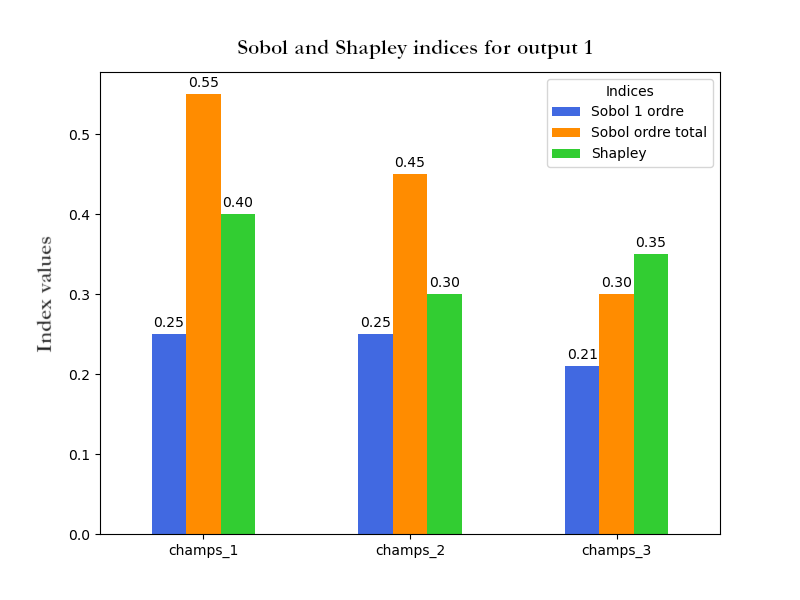

- As the input fields in the second phase were correlated, a sensitivity analysis using Shapley indices was carried out to identify the fields that had an influence on the final model outputs.

- A descriptive statistical analysis and correlation matrices were also realised.