Context

Aubert & Duval, a specialist in high-end metallurgy, is a world leader in the design, development and manufacture of forged and closed die-forged parts, bars and powders in high-performance steels, superalloys, aluminium and titanium.

The time taken to develop new alloys is often very long, and there is no guarantee that the field of the possible will be explored or that an alloy with maximised performance will be obtained. The use of Artificial Intelligence makes it possible to reduce the time taken to design and bring new alloys to market, while significantly reducing the amount of material required for alloy development.

This is the context for this project, the aim of which is to use a database of steel grades for case-hardening (a thermochemical process that increases hardness). When a steel grade is developed, the aim is to achieve the right compromise between core and shell hardness. The objectives of this study are therefore :

- Building a Machine Learning model capable of predicting the hardness of case-hardening steel grades based on the compositions of the phases after tempering;

- Performing a reverse engineering approach in order to highlight compositions that guarantee the desired steel hardness.

In order to encourage the development of in-house skills at Aubert & Duval, this service was delivered in a collaborative and agile mode, allowing greater flexibility and encouraging the involvement of Aubert & Duval teams throughout the service and the transfer of skills.

results

- Descriptive analysis of available data using Python notebooks:

- Histograms;

- Boxplots;

- Correlation matrix;

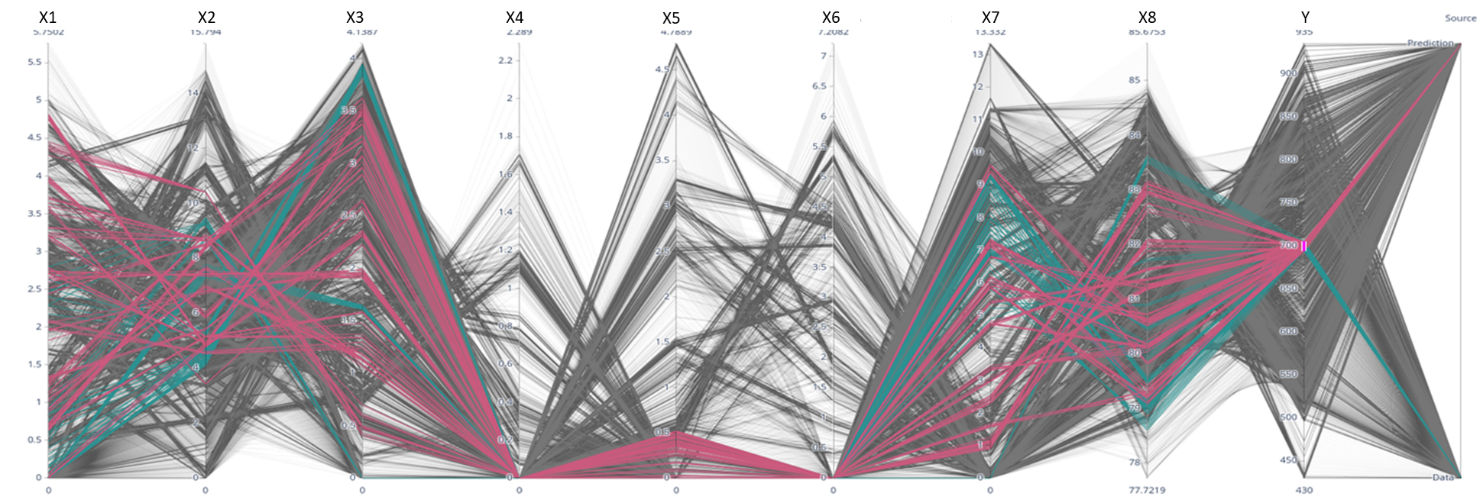

- Parallel coordinate diagram to establish links between the values taken by the different variables.

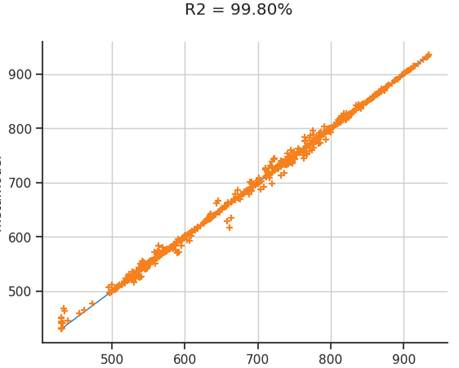

- Construction of Machine Learning models to predict the hardness of case-hardening steels. Extraction of the importance of the variables in the model prediction.

- Reverse engineering to determine the most interesting compositions from a set hardness. Use of gradient descent algorithms and particle swarm optimisation algorithms.

- Provision of interactive notebooks summarising the results of the study and enabling customers to explore their data themselves.

Figures :

Figure 1 : Match plot between the values of the response variable and the predictions of the Machine Learning model

Figure 2 : Parallel co-ordinate graph showing, for given output values, the combinations of associated entries in the available database (blue) and the combinations found using inverse optimisation (pink).