Context

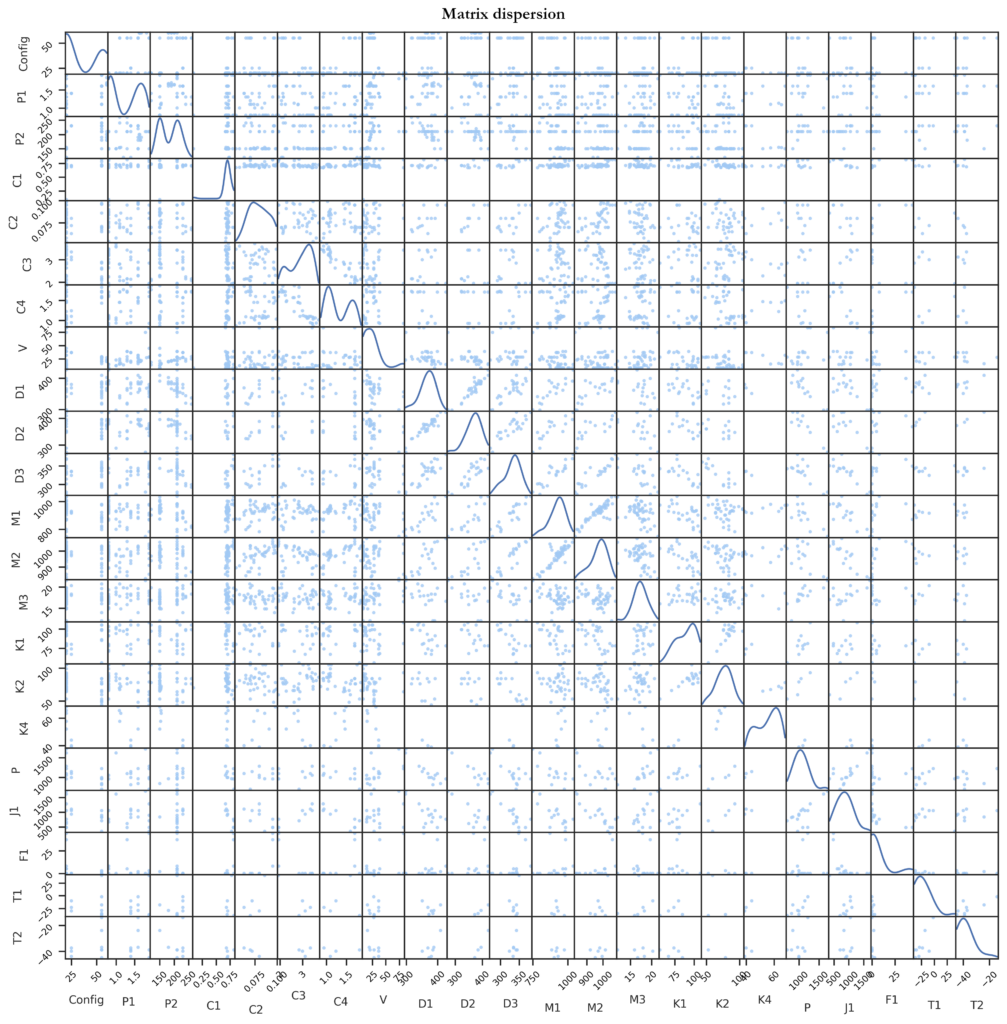

Our customer asked us to develop a tool to help predict weld characteristics, as part of the optimisation of its industrial processes. The main objective was to create an ergonomic, high-performance interface that would enable existing data to be used effectively to improve the quality and reliability of welds.

The tool had to incorporate various advanced regression methods in order to offer accurate predictions while taking account of the associated uncertainties.

The application had to enable parameters to be customised, model performance to be displayed and algorithms to be updated by adding new data. Thanks to this solution, our customer benefits from greater control over the parameters influencing weld quality, reducing the risk of errors and optimising quality control.

Results

- Design and development of a Human Machine Interface (HMI) with three main tabs:

- Home: configuration of parameters and access to recent training sessions;

- Prediction: input data, generate predictions and analyse results;

- Training: update models by importing new data.

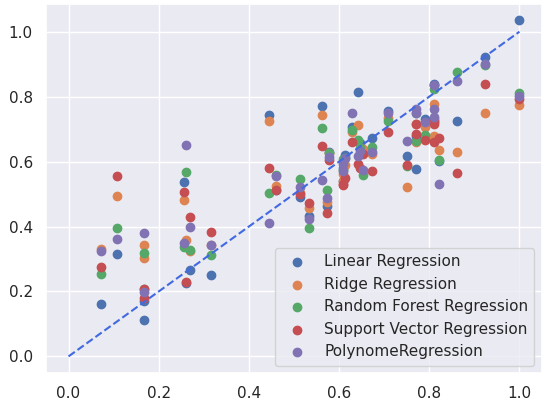

- Integration of advanced regression methods:

- Linear regression;

- Lasso regression;

- Ridge regression;

- Random decision forest;

- Support vector machine (SVM);

- Polynomial regression.

- Implementation of Leave-One-Out cross-validation to optimise model robustness;

- Display of results with 95% confidence intervals;

- Definition of critical thresholds for prediction analysis;

- Comparison of models before and after training to ensure continuous improvement.