Context

Avignon Ceramic is a manufacturer of ceramic cores used to create recesses in the heart of castings.

Avignon Ceramic has observed, for a specific family of cores, a high variability in the scrap rate (blisters, cracks) within their production, and wishes to understand the causes of this phenomenon. An initial statistical study was therefore carried out to determine the parameters influencing the scrap rate, based on a database containing manufacturing, injection and firing parameters and workshop conditions for various products.

In addition, Avignon Ceramic has found that the throughput time for different production stages is longer than the theoretical time initially forecast. A second statistical study was carried out in order to determine the stages responsible for the discrepancies between theoretical and actual times.

For this, a database is available with the start and end dates of each stage in the production process for the various products.

Results

- Formatting and cleaning of databases supplied by the customer: deletion of rows with outliers, imputation of missing data, etc.;

- Feature engineering: transformation of raw data into characteristics likely to better represent the business problem (for example: from the mixing and injection dates, create a dough age variable);

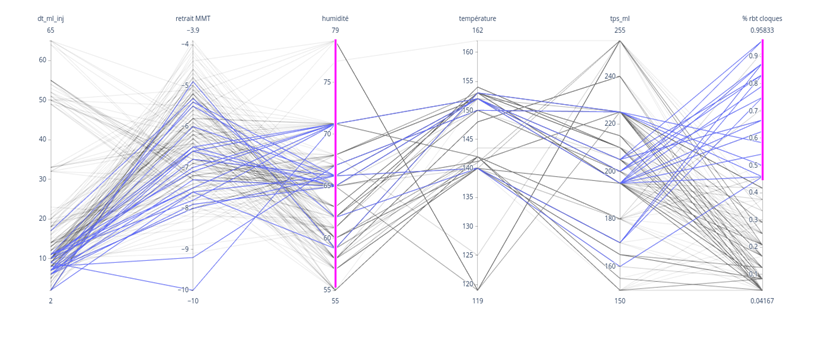

- Descriptive analysis: histograms of the different variables, studies of correlations between variables, univariate and bivariate analysis, parallel coordinates plot to establish links between the values taken by the different variables, etc.;

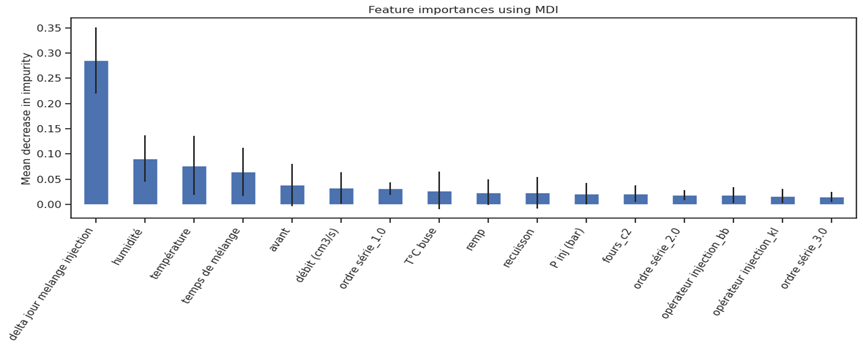

- Construction of a Machine Learning model to predict the scrap rate and extraction of the importance taken by the variables in predicting the model;

- Provision of interactive notebooks summarising the results of the study and enabling the customer to explore the data themselves.

Figure 1: Blisters on ceramic part

Figure 2: Parallel coordinates plot for establishing links between the values taken by different variables

Figure 3: Graph showing the importance of the different variables in the scrap rate prediction model